Home » Die Concepts

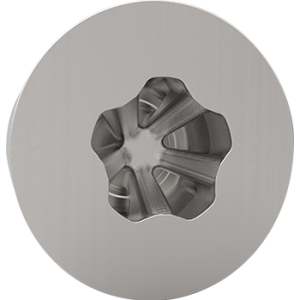

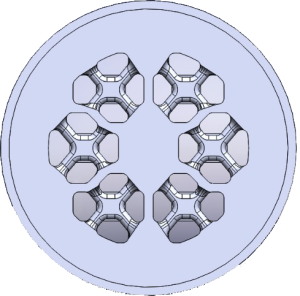

Die Concepts

- What we do

The basic dies we seek to develop are based on our experience.

- 18 Dies

Thanks to our dies, aluminium can be extruded into a wide variety of shapes, making it ideal for use in construction, transportation and industry in general.

- Die Concepts